The VML type valve is a slow opening single-stage solenoid valve, normally closed (open when energized). This type of device is suitable for air or gas blocking and releasing controls, required in gas power burners, atmospheric gas boilers, industrial kilns and others gas consuming appliances.

Feature

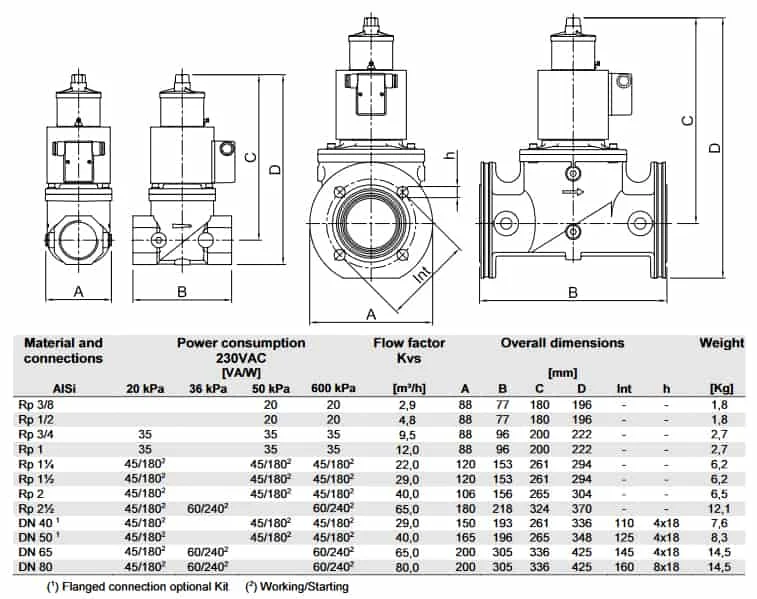

- The valves are made of aluminum alloy die-cast, with a wide range for inlet/outlet connections from DN10 up to DN80.

- Pipe connections meet group 2 and backpressure sealing is compliant with class A, according to EN161 requirements.

- Suitable for use with air and non-aggressive gases included in the 1, 2 and 3 families (EN 437). Special versions for aggressive gases (Biogas, COG).

- The whole range can be provided in Ex-proof execution, for use in Zones 2 and 22, according to 94/9/EC Directive (ATEX).

- The valve is open only when energized: if, for any reason, power supply goes down, the valve closes immediately (intrinsic safe).

- Suitable for cycle operation and qualified for continuous service (100% ED).

- Equipped with max. flow rate and start flow rate adjustment.

- An incorporated fine mesh filter protects the valve seat and disc as well as downstream components and prevents dirty contamination (except 6 bar models).

- Provided with G1/4 pressure gauge on two sides in the inlet chamber, to connect manometers, pressure switches, leakage tester or other gas equipments. Flanged models are provided with gauges also in the outlet chamber.

- The coils are provided with terminal box or with ISO 4400 plug (optional). Both systems are provided with suitable cable gland to avoid water and dirty contamination.

- All components are designed to withstand any mechanical, chemical and thermal condition occurring during typical service. Effective impregnation and surface treatments have been used to improve mechanical sturdiness, sealing and resistance to corrosion of the components.

Specification

- Connections:

Gas threaded f/f ISO 7-1 from Rp1/2 to Rp2½

Flanged PN16 – ISO 7005 from DN40 to DN80

- Voltage rating:

230 VAC 50/60 Hz

110 VAC 50/60 Hz

24 VAC/DC

- Voltage tolerance: -15% ... +10%

- Power consumption: see charts

- Ambient temperature: -15°C ... +60°C

- Max. operating pressure:

200 mbar (20 kPa)

360 mbar (36 kPa)

500 mbar (50 kPa)

6 bar (600 kPa)

- Flow capacity: see charts

- Closing time: < 1 second

- Opening time: Adjustable

- Filter (except brass models): 600 μm

- Protection class:

IP54 (EN 60529)

(optional IP65 with cable)

- Cable gland:

M20x1,5 (EN 50262) for terminal box

PG 9 for standard plug

- Wires cross-section: 2,5 mm2 max.

- Electrical safety: Class I (EN 60335-1)

- Coil winding insulation: Class H (200°C)

- Coil thermal resistance Class F (155°C)

- Materials in contact with gas

Aluminium alloy

Brass Stainless steel

Plated steel

Anaerobic adhesive

Nitrile rubber (NBR)

Fluoro elastomer (FPM)

Polytetrafluoroethylene (PTFE