DESCRIPTION

F-5500 tersedia dalam tipe inline maupun instertion dan dilengkkapi dengan interface yang mudah digunakan. Versi standar flow meter ini menggunakan 4-20 mA analog output dan interface RS485 yang kompatibel dengan BACnet® MS/TP or Modbus® RTU. Konfigurasi signal output yang tersedia menggunakan 4-20 mA analog output dan sebuah programmable pulse output. Model pulse output nya juga tersedia dengan HART.

APPLICATIONS

Accurate sub-metering of natural gas & propane for:• Tenant space usage

• Boiler efficiency

• Campus monitoring

Also ideal for monitoring:

• Compressed Air

• Medical gases

• Other industrial gases

GENERAL SPECIFICATIONS

FLOW ACCURACY

Natural Gas / Propane Gas± 1.0% of reading from 500 – 7000 SFPM

± 2.0% of reading from 100 – 500 SFPM

Compressed Air & other high velocity calibrations

± 1.0% of reading + 0.5% of scale over a 100:1

turndown

TEMPERATURE ACCURACY

± 1.0°F over the range of -40 to 250° F

OVERALL FLOW RANGE

15 to 35,000 SFPM

OPERATING RANGE FOR COMMON PIPE SIZES15 to 7000 SFPM in schedule 40 pipe

|

Pipe Size (Inches)

|

Flow Rate (SCFH)

|

|||

|

Min

|

Max

|

|||

|

¾

|

3.3

|

1,560

|

||

|

1

|

5.4

|

2,521

|

||

|

1¼

|

9.3

|

4,362

|

||

|

1½

|

13

|

5,938

|

||

|

2

|

21

|

9,740

|

||

|

2½

|

30

|

13,964

|

||

|

3

|

46

|

21,562

|

||

|

4

|

80

|

37,130

|

||

|

5

|

125

|

58,350

|

||

|

6

|

181

|

84,263

|

||

|

8

|

313

|

145,912

|

||

FEATURES

BACnet MS/TP or MODBUS RTU -The standard F-5500 includes an RS485 output that provides BACnet MS/TP or Modbus RTU. Data reported to the network includes flow rate and total, temperature

and elapsed time since reset.

User Friendly Interface / Display -

The bright, easyto-read, backlit display and intuitive menu structure simplify page navigation and allow for field programming. Free utility software is also available for programming

and data logging.

Provides for Field Validation of Calibration -

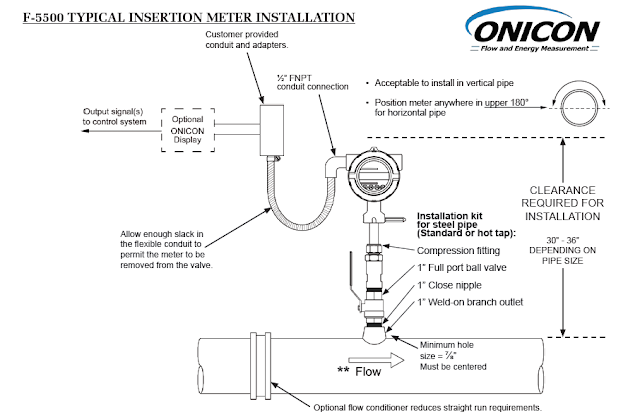

F-5500 internal diagnostic functions include a zero flow calibration check. This fast, easy to perform, test allows for field validation of the factory zero flow calibration. The utility software provided with the meter allows you to print a certificate validating the test results. Insertion Meters Can Be Installed Without Interrupting

Gas Service* -

ONICON’s hot tap design allows for installation without interruption to the gas service. The meter can also be removed for service without disrupting flow.

Highly Accurate Over a Wide Operating Range -

Our proprietary direct digital control sensing circuitry is very stable yet highly responsive to changes in flow. This design allows for accurate flow measurement over a very wide operating range (over 1000:1 for the inline version). It also makes the meter ideal for measuring low flow rates.

Excellent Value -

ONICON insertion style meters are accurate, easy-to-use and reliable. They are also priced independently of pipe size. This makes them an excellent value, particularly in larger diameter pipes.

CALIBRATION

Every ONICON flow meter is wet calibrated in a flow laboratory against standards that are directly traceable to NIST. A certificate of calibration accompanies every meter.

* Installations must comply with federal, state and municipal building codes. Review all proposed combustible gas installations with your local code enforcement officials before attempting any installation.

METHOD

Thermal mass flow utilizing direct digital control sensing circuitry

PIPE SIZE RANGE

Insertion style - 1½” through 24” nominal diameter

Inline style - ¾” through 6” nominal diameter

INPUT POWER

12 - 28 VDC, 6W minimum power

FLUID TEMPERATURE RANGE

-40° F to 250° F

AMBIENT TEMPERATURE RANGE

-40° F to 158° F

MAXIMUM OPERATING PRESSURE

Insertion flow meter:

Standard process adapter fitting - 60 PSIG (4.1 barg) max

High pressure adapter fitting - 150 PSIG (10.3 barg) max

Inline flow meter:

Flanged-ANSI 150 (230 PSIG at 100˚ F (16 barg))

NPT 300 PSIG (20.7 barg)

All stainless steel ferrules

PRESSURE DROP (@ 2500 SFPM, 70° F and 2 PSIG)

Insertion meter - Less than 0.5” W.C. (H20) in 1½” diameter

pipes, decreasing in larger pipes

Inline meter - (with built-in flow conditioner)

Less than 0.5” W.C (H20) in 2” and larger diameter meters

Less than 0.9” W.C (H20) in 1” and 1½” diameter meters

PROGRAMMING / MEMORY

Factory programmed for specific application. Field programming available through user interface or mini-USB interface and utility program. Non-volatile memory retains all program parameters and totalized values in the event of power loss.

OUTPUT SIGNALS PROVIDED

Analog outputs: 4-20 mA (standard on all models) Select from one of the following options as the second

output:

• RS485 interface: BACnet MS/TP or Modbus RTU

(field selectable)

• Programmable pulse output: Field selectable as scaled

pulse or alarm (Isolated open collector output)

• 4-20 mA with HART FSK (Only available with

programmable pulse output)

MATERIAL

Wetted metal components: 316 stainless steel

ELECTRICAL CONNECTIONS

Enclosed terminal blocks, cable access through two ¾” NPT

conduit fittings

APPROVALS

FM (USA) FMc (CAN): Approved

Class 1, Div 1, Groups B, C, D;

Class 2, Div 2, Groups E, F, G;

Class 3, Div 1; T4, Ta = -40˚ C to 70˚ C;

Class 1, Zone 1, AEx/Ex db IIB + H2 T4;

Gb Ta = -40˚ C to 70˚ C;

Type 4X, IP66/67

CE Mark

EMC Directive; 2014/30/EU

Emissions and Immunity Testing:

EN61326-1:2013

Massachusetts Board of State Examiners of Plumbers and

Gasfitters

Komentar

Posting Komentar

Informasi Pilihan Identitas:

Google/Blogger : Khusus yang punya Account Blogger.

Lainnya : Jika tidak punya account blogger namun punya alamat Blog atau Website.

Anonim :