Introduction

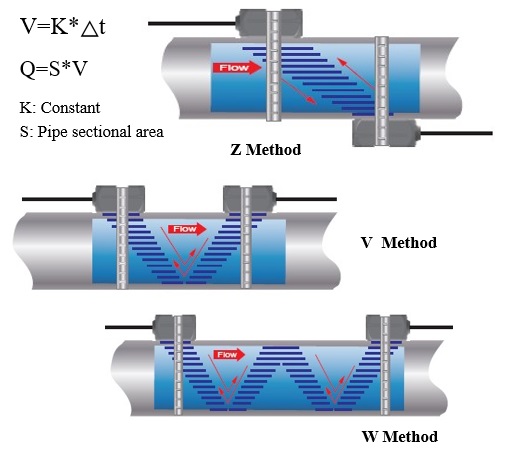

Flowmasonic WUF 620 Transit-time ultrasonic flow meter utilizes the difference of ultrasonic pulse forwarding and reversing flow rate to measure flow. Use a pair of transducers to transmit and receive signals alternately. The Transducer signal travels faster downstream than upstream. Obtain transit-time △t by measuring signal travel time downstream and upstream, the average flow velocity can be detained according to △t and velocity V. The volume flow Q can be calculated out of the flow velocity V and pipe profile S.

Flowmasonic WUF 620 J Series Flowma Portable clamp-on transit-time ultrasonic flow meter utilizes the transit-time principle. The Flowmasonic transducer is mounted outside the surface of the pipe without requirements of flow stop or pipe cutting. It’s very simple and convenient for installation, calibration, and maintenance.

|

| Flowmasonic-WUF-620-J |

Different sizes of transducers satisfy different measuring demands. Plus, select the thermal energy measuring function to achieve complete energy analysis. The Ultrasonic Portable flow meter WUF620J is widely applied in processing monitoring, water balance test, district heating balance test, and energy efficiency monitoring as easy installation and simple operation advantages.

Portable Ultrasonic flow Meter WUF 620 J Series Features

Built-in Chargeable Lithium Battery Can Continuously Work for 50 Hours

- 4 Lines Display Velocity, Flow Rate, Volume, And Meter Status

- Clamp-on Mounted, Unnecessary Pipe Cutting Or Processing Interruption

- Fluid Temperature Range -40℃~260℃

- Built-in Data Storage Is Optional

- Selecting Temperature Sensor PT1000 To Achieve Thermal Energy Measurement Function

- Suitable For DN20-DN6000 Flow Measurement By Selecting Different Size Transducers

- Bi-directional Measurement, Flow Range From 0.01m/s To 12m/s

When selecting a measurement site, it is important to select an area where the fluid flow profile is fully developed to guarantee a highly accurate measurement. Use the following guidelines to select a proper installation site:

- Choose a section of pipe that is always full of liquid, such as a vertical pipe with the flow in the upward direction or a full horizontal pipe.

- Ensure enough straight pipe lengths are at least equal to the figure shown below for the upstream and downstream transducer installation.

- Ensure that the pipe surface temperature at the measuring point is within the transducer temperature limits

- .Consider the inside condition of the pipe carefully. If possible, select a section of pipe where the inside is free of excessive corrosion or scaling.

Performance Index

Read More Article: |

Komentar

Posting Komentar

Informasi Pilihan Identitas:

Google/Blogger : Khusus yang punya Account Blogger.

Lainnya : Jika tidak punya account blogger namun punya alamat Blog atau Website.

Anonim :